Description

Traditional rotary aviation engines – not to be confused with more modern Wankel type engines – are similar to radial engines in outward appearance. Unlike Radial engines, the entire engine spun along with the propeller. Most of these engines were 5, 7, or 9 cylinders. There were a few double-row rotary engines. The rotary engine rose to popularity around a decade after the Wright Brother’s first flights, and peaked in popularity a little before the end of WWI. It was a time of rapid technological advancement, unorthodox solutions to complex problems, and acceptance of low mechanical reliability.

Few people of today appreciate the genius of the rotary engine. Not only did the radial position of the cylinders allow for the highest displacement in a given package size, but the rotary nature of the engine allowed for significant weight reduction. The engine was literally its own flywheel, saving massive amounts of weight and allowing much smoother power than would have been realized with other formats. Additionally, the rotating assembly did not oscillate. Therefore, the stationary crankshaft needed neither balancing nor counterweights. In a day when maximum RPM and airspeeds were both low, the rotary engine had forced airflow cooling at all speeds. The rotary engine dominated in early early to middle WWI. However, it suffered from cooling issues that served to practically limit it to around the 200 hp mark.

Even though few of these engines are still around, the rotary engine’s effect still lingers on our air system today. The high gyroscopic loads made right turns to be quite difficult, and this is likely the reason behind our dominant left-handed traffic patterns and for why the pilot sits in the left seat. Safety experts are glad the rotary is gone, citing its quirky, gyroscopic issues and low reliability. Since it was lubricated with a two-stroke like total loss oil system, the environmentally conscious pilot are glad it is no longer flying. Since the oil that was used to lubricate it was castor oil, pilots who prefer not to wear diapers while flying are glad it is gone as well.

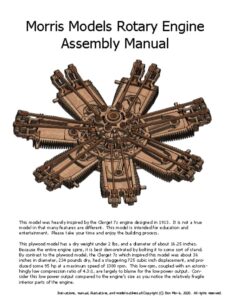

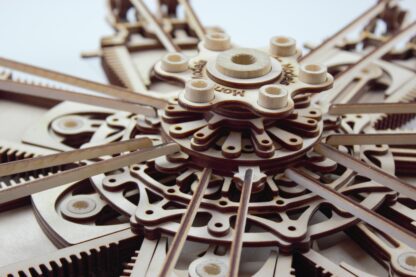

Our rotary engine is inspired heavily by the French Clerget series of engines. Most of the Clerget engines were 9 cylinders, but they did make a seven cylinder version. So did we. It features an articulating and slave connecting rod system in the rotating crankcase. The forward valve case features a simple but elegant gerotor-like valve mechanism running on twin eccentric shafts fastened to the front of the crank. This mechanism seems to be unique to the Clerget engine. Compared to our radial engine, the cylinders have much fewer cooling fins. The exhaust dumps into the open air in front of the cylinder while on the bottom part of the engine’s rotation. The intake is on the top half of rotation. Our engine has a stroke of 2 inches and a bore of 2 inches. It measures about 16 inches in diameter, and is difficult to display without mounting to some type of base. You can see a lot of details about our model in the video below – including that Clerget type valve mechanism.

This engine kit is an advanced building project, and contains somewhere around 450 pieces. Expect to spend between 10 and 30 hours building the model, although some have spent more time and others have spent less.

This kit is available in single (16 inch), double (32 inch) and triple (48 inch) sizes. Although not absolutely necessary, we recommend that our builders have access to a bench sander.

Building resources for this kit:

Please check out the builders manual to see if this kit is appropriate for you.