Description

The opposed engine format for aviation engines developed alongside the radial engine in the 20’s and 30’s, but was used for smaller engines than the radial format. It was popular for light aircraft because its flattened shape allowed pilots to see over the noses of their aircraft – sometimes even while taxiing. It features opposing pairs of cylinders working outwards horizontally from a common crankshaft. Engines with this format have even numbers of cylinders.

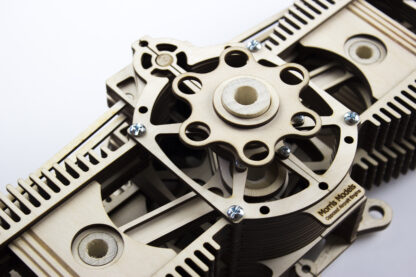

While some builders built two cylinder and eight cylinder opposed engines, most were either four or six. We delayed the development of this model until we could figure out how to see the moving parts from more than one bank of cylinders. In the end, we chose to run the pistons back and forth on tiny tracks in the cylinders. We are calling this a skeleton engine format, and it allows an unprecedented visual depiction of what is at this point the standard light aircraft engine.

Our engine is heavily influenced by the current Lycoming O-235, O-290, O-320, and O-360 engines. It is our most detailed model to date, featuring realistic detail right down to the tiny spark plug gaps. It was designed to sit in a flight instructor’s office so that it can be used to teach practical engine principles. In addition to the unique skeletonized model format, this engine is designed to be held together by bolts or screws. This allows it to be disassembled and reassembled much more like a real engine. This makes the engine much more capable of handling day to day use and perhaps abuse.

This model is about 17.5 inches wide and 7 inches tall. It can easily be mounted to a wall, but it is also at home sitting on a shelf. It features two piece connecting rods that can be attached and unattached, authentic details right down to the cooling fins inside the pistons, and the same valve arrangement as a Lycoming engine.

Features:

- Engine can be disassembled and reassembled to show internal parts

- Skeletonized construction allows view of most moving parts at once

- Firing Order: 1-3-2-4 same as Lycoming Engine

- Solid Tappets

- Spring fitted pushrods

- Intake Cam shared by opposing cylinders

- Twin nonfunctional sparkplugs on each cylinder

- Engraved piston rings

- Internal cooling fins in pistons

This engine contains around 350 pieces, and will take about 5 to 25 hours to complete. Please check out our build manual and build video to see if this engine is for you. It is currently available in single (17.5 inch wide) size and double (35 inch wide sizes). It is an advanced build, and we recommend that you have access to a bench top sander in order to complete this build.

Building Resources for This Kit: